AzteQ specialises in the design, supply, installation and support of heat rejection solutions. We do this professionally and successfully for all of our clients.

AzteQ can help ensure the correct equipment is used for the application and provide a cost effective solution to your specification.

Customer hotline 01442 561000

Closed Circuit Cooling Towers

Centrifugal Fan – Plate Heat Exchanger Models: SF / CRF / KSF

Features: Can operate without glycol, belt drives, centrifugal FRC Filter, equipped with heat transfer surface and the heat exchanger can be fully removed and cleaned, low sound (to 35 dB (A) to 10 m), high corrosion resistance, easy maintenance, stainless steel plate heat exchanger, drain points below the lower surface of the pond (complete draining). Typical capacities for 250 kW to 3000 kW.

All the parts of the closed system are accessible and cleanable therefore the cooling performance is guaranteed for many years.

High corrosion resistance is offered using stainless steel casing and structure (plates : minimum grade is AISI304 as standard) => higher water concentration rates that lead to average 30 % water and treatment chemicals savings.

| Features: | Options: |

| No Freezing without glycol | Galv / Z-Steel / X-Steel / 304 SST / 316 SST |

| Low sound | Sound attenuation |

| Low height |

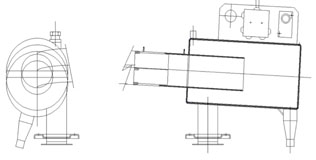

Centrifugal fan – tube bundle Model: VK

Closed circuit cooling towers completely isolate the process cooling fluid from the atmosphere. This is accomplished by combining the heat rejection

equipment with a heat exchanger in a tower. A closed circuit system protects the quality of the process fluid, avoids pollution coming from the make-up water and the ambient air, reduces system maintenance, and provides operational flexibility at a slightly higher initial cost. This technology allows keeping a better and easier control of the complete cooling loop while making it shorter as it is “closed” on the process side.

This system requires less control over the cleanliness and chemical treatment of the loops that is mainly limited to the tower side only.

Another interest (process cooling applications) is to prevent the evaporation loop from pollution coming from the process (metallic particles, fibres etc.).

| Features: | Options: |

| Compact design | Whirl Sintering / 304 SST / 316 SST |

| Low height | Sound attenuation |

| Free cooling & dry cooling | Can be used for indoor applications |

Axial fan - Plate Heat Exchanger Models: KHF / VAPF

Cooling of the liquid in the primary side of a stainless steel plate heat exchanger thus has no direct contact with the air. The secondary side will spray over the top of the tower like the open system. The secondary circuit includes a 100% water flow FRC filter and circulation pump. Typical capacities from 250 kW to 4000 kW.

| Features: | Options: |

| No Freezing without glycol | Galv / Z-Steel / X-Steel / 304 SST / 316 SST |

| Full cleaning on primary and secondary sides | |

| Very low power consumption |

FRC Centrifugal Filter Patented

A closed cooling tower has a primary circuit (to the process), and a secondary circuit: the evaporative circuit. In contact with air, the evaporative circuit accumulates suspended solids. Because of the evaporation, this water, if there is no bleed off, concentrates the salts. In order to keep this secondary circuit clean, without manual maintenance, Jacir has invented the following FRC (cyclonic filter) system. Cleaning and deconcentration in one, Weapon against Legionella : clean circuit 100 % flow filtered every 1.2 minute! No filter maintenance: automatic cleaning with deconcentration. Operation free. No spares, no consumables.

| Features: |

| Simple and efficient against Legionella |

| Very high, 60 µm filtration efficiency on the full flow unlike limited side stream filtration |

| Inductive blow-down (sensor) installed into the filter |

| 100% water flow rate filtered every 1.2 minutes |

AzteQ can supply and where required, install a range of water treatment & Legionella control solutions, associated with the safe operation of Cooling Towers and Hybrid Coolers.